It's made for taste

It's made for taste

Based on the atomizing mechanism of the bottom layer, the preparation technology of atomizing core and the design concept of atomizing platform are combined more than 800 days devoted to research, more than 20,000 times of analysis and experiments, the fifth generation of technological innovation.

Do intensive research

Analysis and experiment

Technological innovation

PURLAVA atomizing core technology, double Omega airway technology, gas-liquid separation technology, condensate management technology.

Fired at 1200℃

The oil supply area

Micropores are

evenly distributed

Oil transfer speed increase

· H-form exclusive structure patent

· Food grade ceramics harmless to human body

· Exclusive Ω heat wire technology | heat deformation resistance high heating efficiency

· Custom ceramic aperture, the best taste of smoke oil

· Regular shape, easy to automate production

Through unique airway design, aerosols are unobstructed, significantly improving suction smoothness and reducing condensate generation.

The air flow passes through the 100μm class micro channel to balance the negative pressure of the fume tank. At the same time block the leakage of smoke oil, the whole process to ensure the stability of the flow of smoke oil.

Carefully designed labyrinth structure, deposit condensate, to ensure that the smoke oil does not leak out.

In gas safety, taste fullness, structural protection and other aspects of the world's top level, Bring users a sense of satisfaction and unparalleled experience.

Gas safety

Mouthfeel fullness

Structural protection

Sweetness

Taste

Atomization

Efficiency

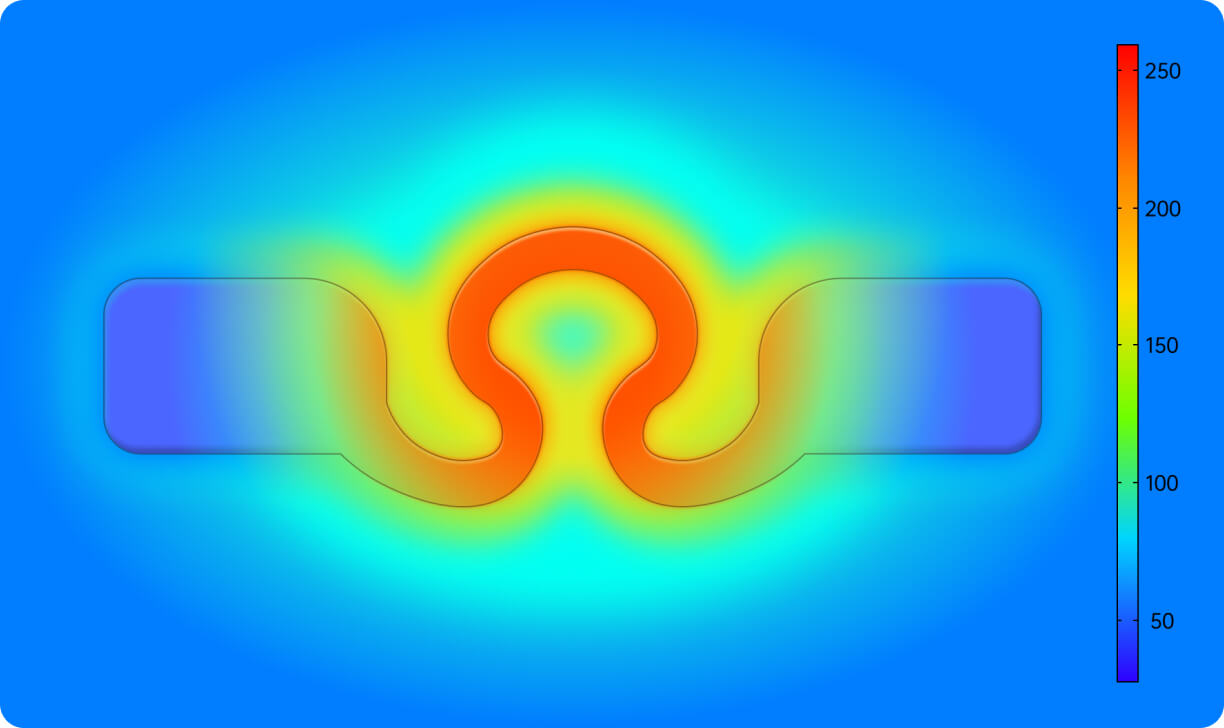

With a higher overall thermal field temperature per unit area of the ceramic element, heat is more concentrated, facilitating the efficient atomization of e-liquid and ensuring a superior experience.

MAX: 332.7℃

MAX: 254.4℃

A new formula featuring specialized microstructures and high corrosion resistance has been designed and developed on the heating film. This achieves thorough e-liquid atomization, improves atomization efficiency, and elevates the aroma and sweetness delivery.